Adiamix has a production site specializing in high speed machining of raw cast parts in medium and large series. Our extensive know-how mainly meets the requirements of material handling equipment manufacturers , but can also be applied to several other sectors.

The term machining includes all the techniques of manufacturing parts by material removal . The basic principle of the process is to remove material using a machine tool to shape a blank and bring it to its final shape. Different tools are used to perform the operation: milling machine, drill, boring machine, mortiser, planer, machining center, etc. Numerically controlled machine tools are then used to manufacture the parts in medium and large series.

Machining can be done in the traditional way or at high speed (HSM). Whatever the technique or tool chosen, the manufacturing steps are similar:

Adiamix uses high-performance numerically controlled machines to produce its machined parts. These CNC machining techniques have many advantages for companies:

Adiamix has a production site specializing in the machining of foundry parts. Based in Orne, our team of experts manufactures prototypes and metal parts in medium and large series (more than 700 tons of parts are produced per year) from different metal materials: steel , cast iron, aluminum…

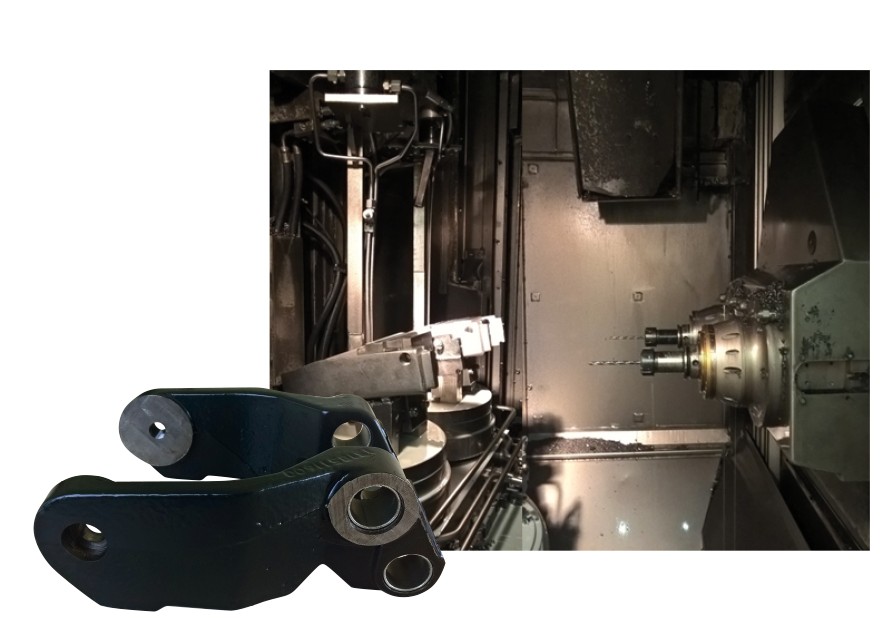

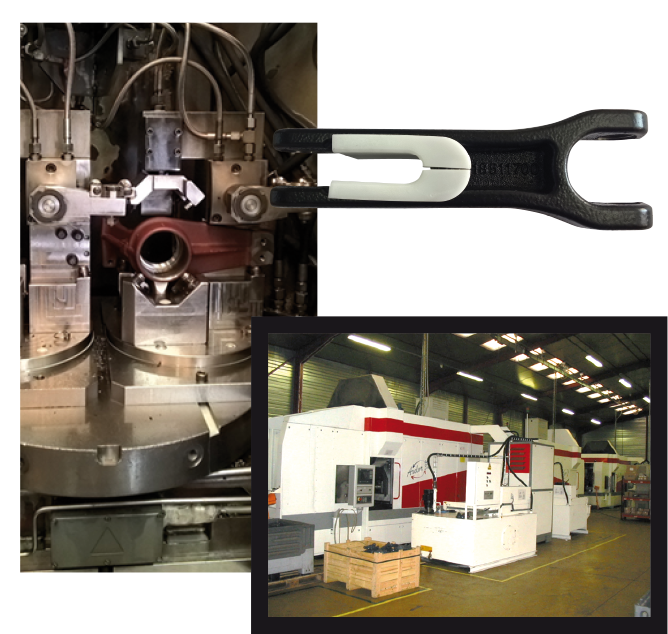

Our site has a complete machine park with an annual machining capacity of 15,000 to 100,000 pieces (300 mm x 300 mm x h = 450 mm). The machine park is equipped with 3 Axelor 32 machining centers with juxtaposed bi-spindles. These powerful CNC machines allow us to simultaneously machine two parts per cycle. Automatic clamping systems on a rotating plate also ensure the perfect holding of the machined raw castings.

Adiamix mainly manufactures castings for material handling machine builders . Our machine park is particularly suited to the requirements of this sector, requiring parts with specific shapes and dimensions.

Parts for lifting devices, fasteners & nbsp;: our production allows material handling professionals to manufacture different machines such as forklifts, stackers, pallet trucks or order pickers. Many reference brands regularly call on our expertise – & nbsp ;: FENWICK, BOSCH, STILL, CROWN, JUNGHEINRICH, etc.

Our production site also manufactures foundry parts for other industries. The raw part requested must however correspond to the size and weight criteria of our machine park.

Adiamix supports its clients in all stages of their project. After analyzing your needs, we design a prototype and then, after validation, produce your parts in series according to your specifications. Call on our machining specialists and our know-how! We are at your disposal to advise you and take charge of the manufacture of your machined parts.